sus630 stainless steel

SUS630 stainless steel (17-4PH / 1.4542) is one of the most popular and most commonly used stainless chromium-nickel alloy steels, copper added, precipitation hardened, with a martensitic structure. It is characterized by high corrosion resistance while maintaining high strength properties, including hardness. Steel can operate in a temperature range of -29°C to 343°C while retaining relatively good parameters.

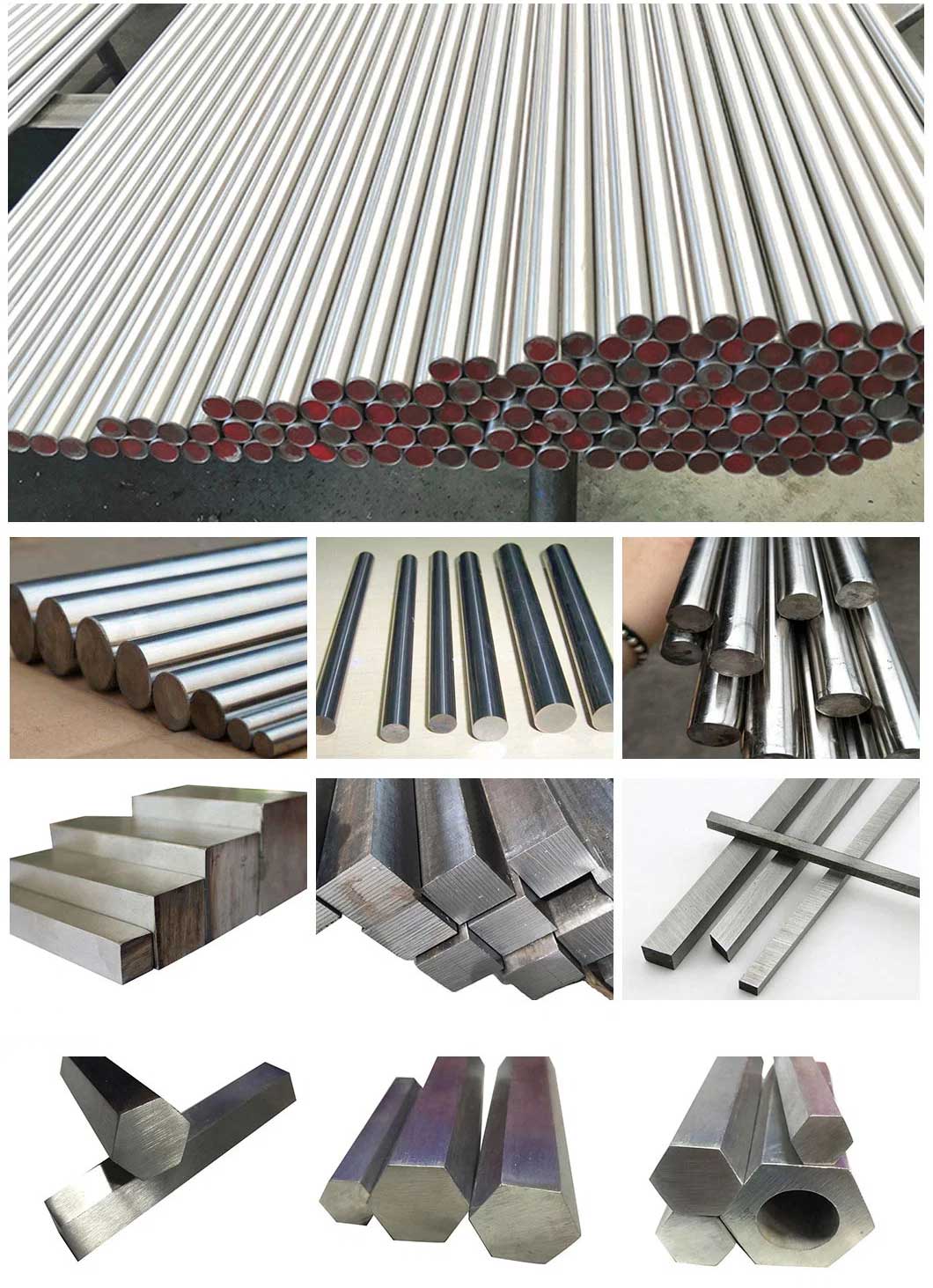

17-4PH, sus630 and X5CrNiCuNb16-4 / 1.4542 are available as round bar, plate, flat bar and cold rolled strip. The material is widely used in heavy machine components, bushings, turbine blades, couplings, screws, drive shafts, nuts, measuring devices in the aerospace, marine, paper, energy, offshore and food industries.

Email: [email protected]

WhatsApp: 0086-18301953841

| Material | Known As | Material Specification | Stock Form | (Min.–Max. mm) |

|---|---|---|---|---|

| SUS630(ST) | S17400 | JIS G4303 JIS G4311 |

Cold finished round bars | φ3-13 |

| Peeled round bars | φ14-200 | |||

| Hex bars | H10-46 | |||

| SUS630 H900 | S17400 | JIS G4303 | Peeled round bars | φ10-200 |

| SUS630 H1025 | S17400 | JIS G4303 | Peeled round bars | φ10-150 |

| SUS630 H1075 | S17400 | JIS G4303 | Peeled round bars | φ10-150 |

| SUS630 H1150 | S17400 | JIS G4303 | Peeled round bars | φ10-200 |

| 17-4PH(ST) | S17400 | ASTM A564 ASME SA564 AMS 5643 |

Peeled round bars | φ10-160 |

| 17-4PH H1025 | S17400 | ASTM A564 ASME SA564 AMS 5643 |

Peeled round bars | φ16-100 |

| A286(SUH660Equivalent) | S66286 | ASTM A453 B&D /A638 Type2 ASME SA453 B /SA638 Type2 AMS5732 GE S-400, GE S-1000 NACE MR0175/MR0103 |

Peeled round bars | φ8-127 |

* For other grades and sizes of material as well as plates/sheets and other shapes, we offer grades: SUS630 (17-4PH) H900, H1025, H1075, H1150 and DH1150 (Double Aged); these grades can quickly convey diameters up to 13- 500mm of material.

Chemical Component

| Grade | C | Mn | P | S | Si | Cr | Ni | Cu | Cb+Ta |

| 630 UNS S17400 | 0-0.07 | 0-1 | 0-0.04 | 0-0. 030 | 0-1 | 15-17.5 | 3-5 | 3-5 | 0.15-0.45 |

Forming Option

1 Hot rolling process.

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging.

Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.